Equiplog

The Equiplog Data Logger by G-Tek is a cutting-edge solution for real-time equipment performance monitoring, specifically designed to ensure compliance with WHO PQS E006/DL01.2 and E006/EM0.1.2 standards. This advanced device collects and stores performance data locally or in the cloud, with a capacity for up to one year of storage. Users can easily access historical data for the last 30 days directly from the display, eliminating the need for downloads or computer connections.

Engineered for optimal temperature monitoring during the storage of vaccines and other medical products, the Equiplog is pre-configurable to meet all three EMS levels as per WHO PQS guidelines. It efficiently records appliance data objects, maintains relative time, and generates standardized logger data accessible to other monitoring systems, such as ILR and vaccine freezers. Throughout the measurement program, sensor input readings are continuously monitored and saved, ensuring data integrity.

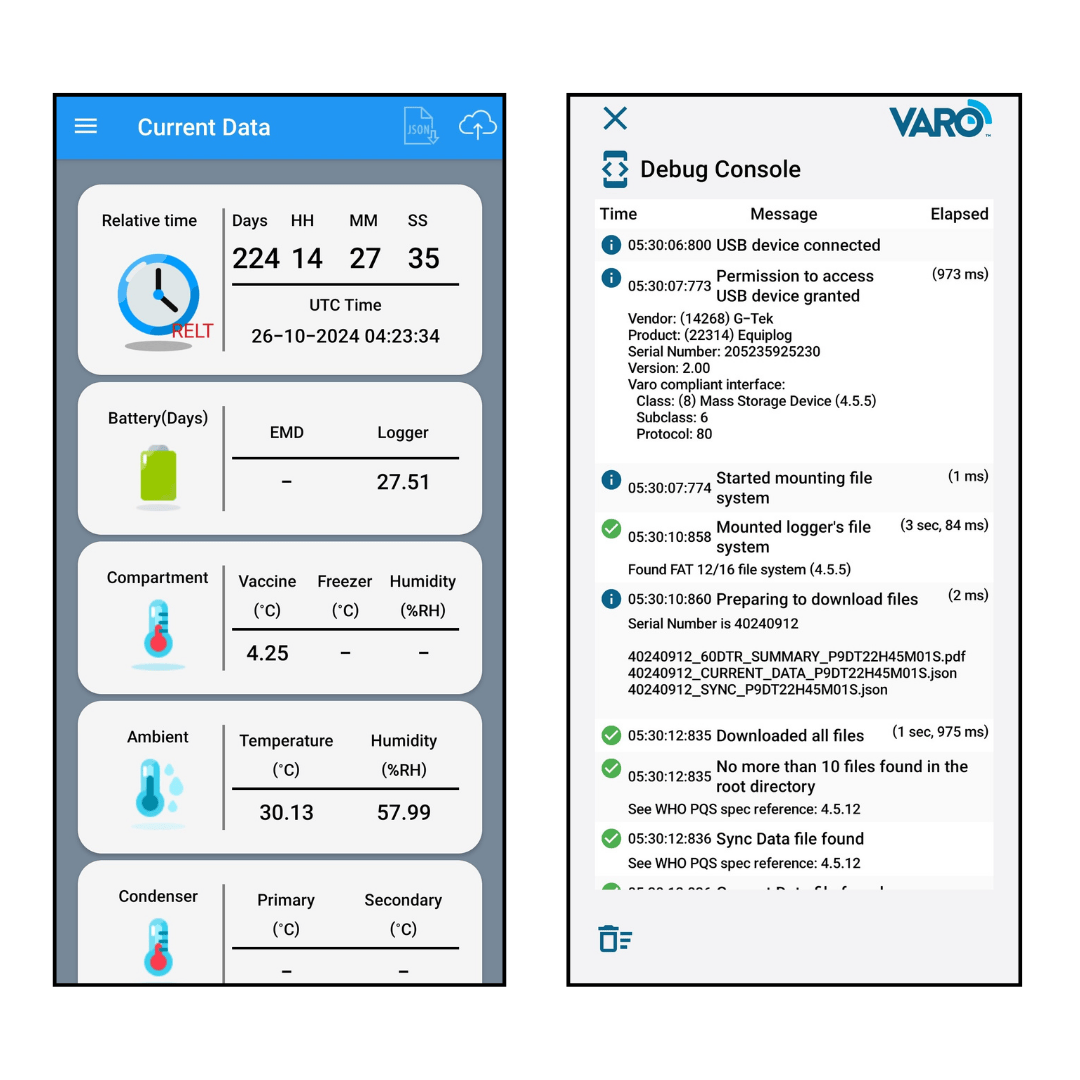

Key features include compliance with WHO PQS E006/DL01.2, E006/EM0.1.2 and E006/DS01.2, M2M interface for appliance monitoring, compatibility with SECOP compressors and a USB Type-C port for easy data access. The logger offers model ranging from a Level-1 to Level-3 of EMS levels. With the functionalities like OLED display, event indications for alarms, error codes, mobile app integration, and real-time cloud data access, the Equiplog Data Logger ensures efficient monitoring. It is also compatible with the Varo App on your smartphone, providing instant cold chain insights sent directly to your inbox. Equipped with a rechargeable battery, it is a reliable tool for maintaining cold chain integrity and the safe storage of medical products.

Features

Key Features:

- WHO/PQS/E006/DL01.2 Compliant

- WHO/PQS/E006/DS01.2 Compliant

- WHO/PQS/E006/EM01.2 Compliant

- Meets the requirements for all three EMS levels

- Compatible with the Varo App on your smartphone for instant cold chain insights sent directly to your inbox

-

M2M Interface for Appliance Data Monitoring:

- Compartment temperature and door opening

- Appliance supply and compressor On/Off time

- Ambient temperature and humidity

- Connects to SECOP compressors

- MODBUS RS485 master to connect to the controller

- USB Type-C port for M2M data access

- 1 year of data storage with a PDF report of the last 60 days

- Direct PDF summary report of the last 60 days as per WHO PQS guidelines

- Standard JSON format files compatible with all appliance data objects

- Rechargeable battery with an operating life of 10 years*

-

Model options to choose from:

- Level-1: Data Logger with M2M Interface

- Level-2: Integrated EMD with local communication

- Level-3: Integrated EMD with local and remote communication

- 1.5” OLED intuitive display (optional) with multi-function menus

- Resolution of 0.1 °C for display and storage

- Local date and time setting option

- History data view of the last 30 days on display

- Event indications such as alarms, door open, power outage, etc.

- Audio-visual indication for temperature alarms

- Audio-visual monitoring enable/disable option

- Error codes for fault conditions in the appliance

-

Mobile Application (Optional):

- Data viewing and upload to the cloud server application

- GSM add-on module feature (optional)

-

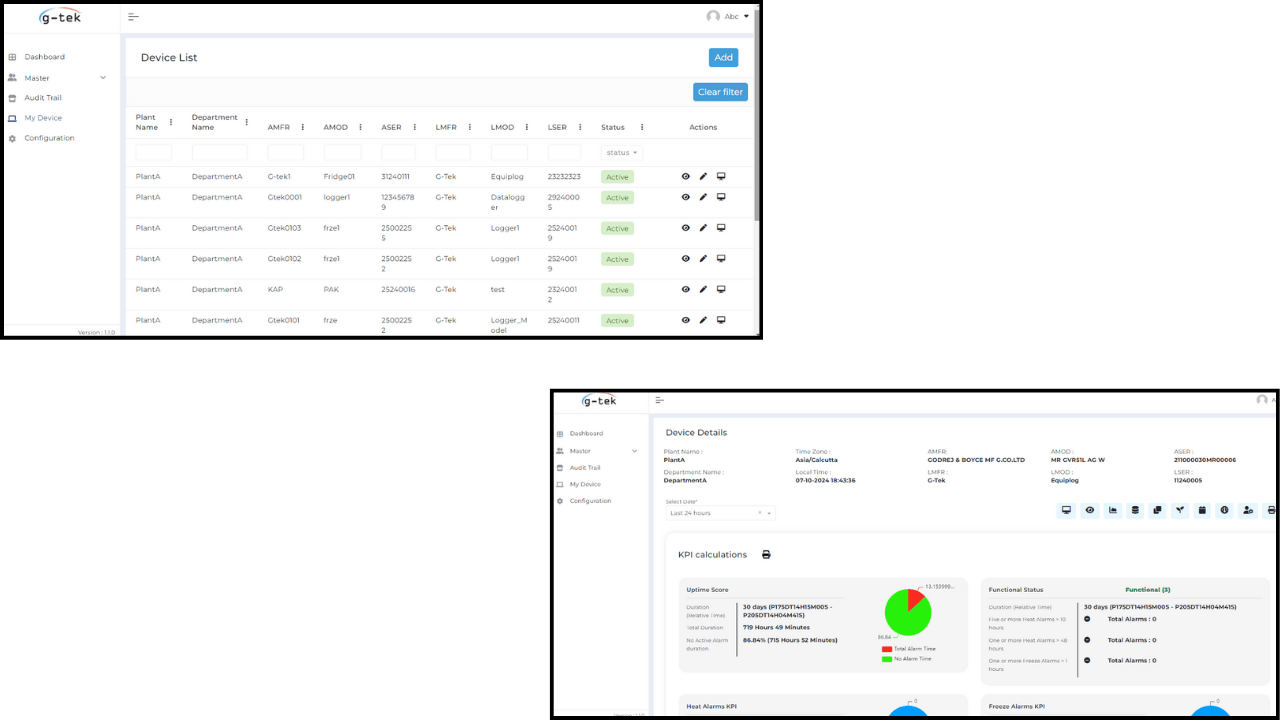

Cloud Server Application for detailed analysis and report generation:

- Real-time data monitoring on the cloud server application

Specification

| Model | Equiplog ( 9994x series) |

| Display and Operator Panels# | |

| Display Type# | 1.5” OLED display (128×128 pixel Gray scale) with,

|

| Status Indicator# | Status LEDs for

|

| Panel Keys# | For Data Logger without Display: 1 key for data recording start; 1 key for alarm acknowledgment For Data logger with Display: 3 multi-purpose keys; 1 key for alarm acknowledgment |

| Analog Inputs | |

| No. of Inputs | 8 Sensors 2 x Temperature sensors (Vaccine, Freezer compartment) 2 x Door sensors (Vaccine, Freezer compartment) 2 x Potential free contact for Compressor On/Off 1 x Ambient Temperature & Humidity sensor (Internal) 1 x Temperature sensor for Appliance self Test (Internal) |

| Temperature Sensor | Thermistor – Tayao 10K NTC, 3 mm diameter, 2.5 meter long cable with sealed cap |

| Operating Range (Sensor) |

-40 °C to + 60 °C (-40 °F to +140 °F) |

| Accuracy | ± 0.5 °C for the range -30 °C to + 30 °C; ± 0.7 °C otherwise |

| Temperature Response Time | T90 < 20 minutes as per EN12830:1999 |

| Resolution | ± 0.1 °C |

| Door Sensor# | Magnetic reed switch/Potential free contact |

| Operating range | -30 °C to + 50 °C (-22 °F to +122 °F) |

| Accuracy | Binary, open/closed |

| Response Time | An “open” event is identified whenever door panel is not fully seated in the closed position for proper compartment sealing. |

| Voltage Monitoring Input# | |

| Operating range | -30 °C to + 50 °C (-22 °F to +122 °F) |

| Accuracy | ± 2 % for DC range 0- 72 V ± 2 % for AC range 0- 600 V |

| Resolution | ± 0.1 V |

| Current Monitoring Input# | |

| Operating range | -30 °C to + 50 °C (-22 °F to +122 °F) |

| Accuracy | ± 5 % for DC range 0- 10 A ± 5 % for AC range 0- 30 A |

| Resolution | ± 0.1 A |

| Ambient Temperature-Humidity Sensor | Solid state MEMS sensor# |

| Operating range | -20 °C to + 60 °C (-4 °F to +140 °F) 0 to 100 %RH |

| Accuracy | ± 0.5 °C for the range +10 °C to + 40 °C; ± 0.7 °C otherwise ± 3 %RH for the range 20 to 80 %RH ± 5 %RH otherwise |

| Resolution | ± 0.1 °C ± 0.1 %RH |

| Calibration | Each device accompanies NABL (ISO/IEC 17025) traceable certificate |

| Alarm Details | |

| Heat Alarm Settings* | For Vaccine: +8°C or above for 10 hours; For Freezer: -15°C or above for 60 minutes |

| Freeze Alarm Settings* | For Vaccine: -0.5°C or below for 60 minutes; |

| Door Open Alarm Settings* | For Vaccine: > 5 minutes of continuous door opening For Freezer: > 30 seconds of continuous door opening |

| Power Outage Alarm Setting* | > 24 hours of continuous power outage |

| Alarm Visual | Display shows▲or ▼arrow for alarm Heat/Freeze condition with bell symbol |

| Alarm Audio | Buzzer Output > 65 db. Buzzer will beep in alarm Heat/Freeze condition. For details please refer User Manual. |

| Alarm Acknowledgement | By pressing |

| Alarm Event objects | Heat Alarm: “HEAT”, Heat Alarm Acknowledge: “HEATACK”, Freeze Alarm: “FRZE”, Freeze Alarm Acknowledge: “FRZEACK” Vaccine/Freezer Door Open: “DOOR” Vaccine/Freezer Door Open Acknowledge: “DOORACK” Power Outage: “POWR” Power Outage Acknowledge: “POWRACK” |

| Batch Details | |

| Activation | Data logger without display: By Pressing “Start”  key for more than 10 Seconds. key for more than 10 Seconds.

Data logger with display: By Pressing “Up” |

| Deactivation | Cannot be manipulated, reset or deactivated once activated |

| Data Recording Interval | 15 minutes Pre-fixed |

| Memory | |

| Data Storage | Yes |

| Memory Type | Flash, Non-volatile, Data Retention of more than 20 years |

| Memory Size | 1 year’s data storage and summary PDF report of 60 days |

| Memory Setting | Rollover data records |

| Environmental Parameters | |

| Temperature during Transport and Storage – Device inactivated | -30 °C to + 70 °C with Data logger inactivated except relative timekeeping |

| Temperature during operation | -10 °C to + 55 °C |

| Humidity during Transport, Storage and Operation | 0 to 95 %RH non condensing |

| Altitude | < 2000 meter |

| Power Requirements | |

| Power supply | 12-48 V DC, 2 A (DC adapter) or SMPS with Power output of 15 V DC, 3 A, 35 W |

| DC power Output | 5 V, (0.8 to 1.2 A), Max 5.2 W |

| Power connector | Barrel-type male plug with captive cable connected to the appliance Sleeve diameter: 5.5 mm; Sleeve length: 9.5 mm; Pin diameter: 2.1 mm; Polarity: Pin positive, sleeve negative; Cable type: captive to appliance and easily replaceable by trained technician; cable length: 20 cm |

| Battery | LiFePO4 Rechargeable Battery 3.6 V, 1500 mAH |

| Battery Life | Operating life of 10 Years |

| Battery Backup | More than 30 days* with recommended operating condition for Data Logger without Display. More than 20 days* with recommended operating condition with display operated 4 min/day for Data Logger with Display. |

| Minimum Battery run time after full charging | With 8 hours of charging the Battery, it will run for minimum 48 hours |

| User Interface | |

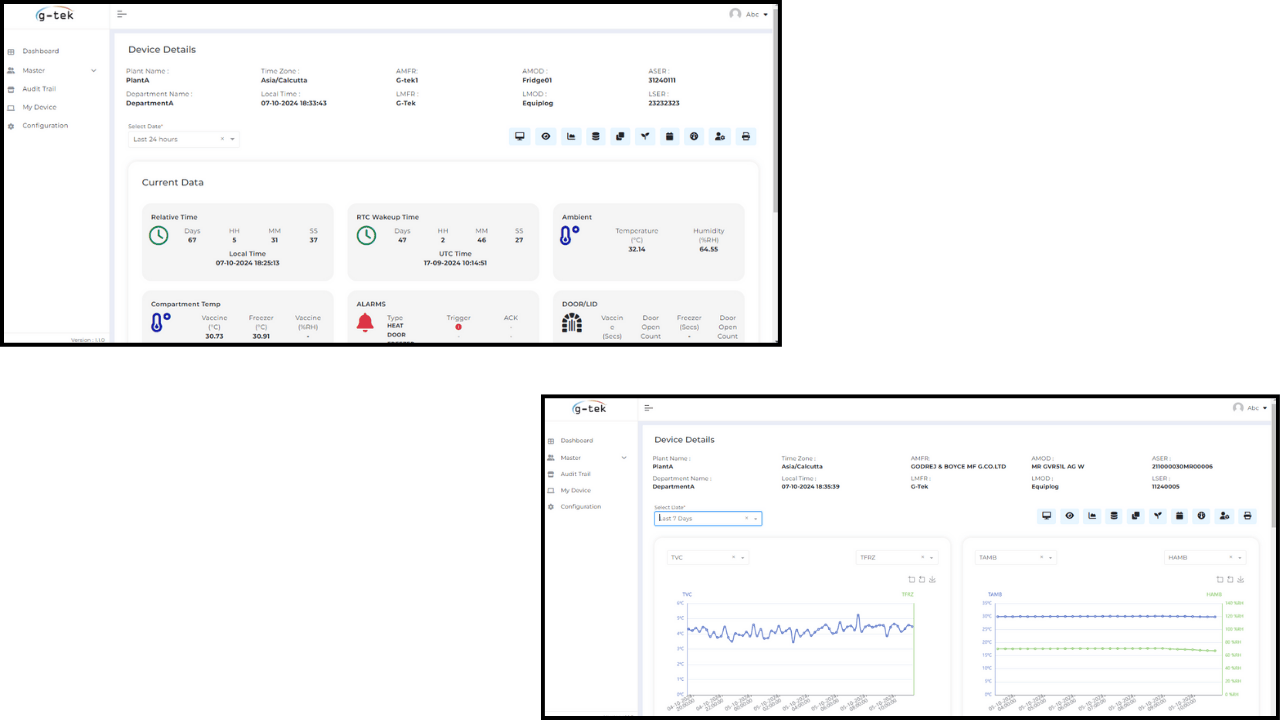

| Home screen view | Display header:Battery Level, Power status, USB symbol, REC status, GSM strength# Main Body: Alarm(s) messages, Alarm trigger (Bell) symbol (if any), Local or absolute# date & time, Alarm status ( ✔/ X) symbol, Current reading for Vaccine Compartment with measurement unit. Footer: Multi day Alarm History markers(▲ or ▼ arrows) (if any) |

| History Data view | Last 30 days history data: day wise overview of vaccine compartment for min, max, average, Heat/Freeze alarm duration, on the display using keyboard |

| Appliance details view | Appliance Manufacturer: Make, Model, Serial Number, PQS code |

| Logger details View | Logger Manufacturer: Make, ID, Serial Number, PQS code |

| Modbus details View | Modbus Communication parameters settings information |

| Linbus details View | LINbus Communication parameters settings information |

| System Live View | Power & Cooling: Power and Compressor status, Temp. & Door: Vaccine, Freezer, Ambient Temperature & Door status Error codes: Error Status for Battery, self test, Modbus, Linbus, Vaccine, Freezer sensor Last data upload#: Date and Time Alarm Monitor: Enable/Disable RTC Setting: Set Local Date and Time |

| Data File Type | Json Data Objects file for data records, PDF file for Summary report |

| Data records in Json objects | As specified in PQS specification protocol WHO/PQS/E006/DS01.2 |

| Time format | Comply with the ISO 8601 Internet Date Time format, Absolute time specified in format: YYYYMMDDThhmmssZ Relative time specified in format: PnDTnHnMnS |

| Logger battery Remaining | Estimated number of days remaining to operate the logger normally on battery |

| RTC Wakeup (RTCW) Time | Relative timestamp of the last time the logger resumed from Off to ON condition. |

| Mounting of device | Data logger is integrated within an Appliance |

| Material | Polycarbonate Plastic: non-breakable, non-corrodible housing |

| On site Installation | Not required |

| Instructions | User manual and Technician manual in Arabic, English, French, Mandarin Chinese, Russian and Spanish. |

| Training | If requested, remote training on installation, on-site use, maintenance of the hardware and download of data via the M2M data interface. |

| Warranty | 1 year from the date of dispatch. Refer to warranty certificate for more details. |

| Service Provision | Replaceable parts of the data logger shall be supplied on request. |

| Communication Details | |

| Data Connector | USB Type-C female receptacle shall be used for data download by external devices and power supply from external devices to the logger in the event the logger’s energy storage is depleted. |

| Connectivity | USB 2.0 Compatible Type-C, FAT16 |

| Data Download Time | Approx. 2 minutes for full data download |

| Physical characteristics | |

| Overall Dimensions (L x W x D) mm |

110 x 80 x 65 mm |

| Cutout Dimensions (L x W) mm |

92 x 45 mm |

| Weight | Approx. 350 gms |

| Conformity Standards | |

| Electromagnetic Compatibility | IEC 61000-6-1/6-3 |

| Resistance to Electrical Storms | IEC 61000-6-1; (IEC 61000-4-2 Basic Standard for applicability of tests) |

| IP Rating | IP 64 (Bezel only) for USB Type- C M2M port connections with left unconnected and when cable is connected to an E-EMD device |

| Pollution Degree | II |

| Installation category | I |

| RoHS, Reach | Compliant (EU directive 2011/65/EU) |

| Verification | In accordance with PQS verification protocol E006/DL01-VP.2 and E006/EM01-VP.2 |

#: Optional Features, please refer to the order code to know about installed options in your device. Sensors are not part of the Data logger and to considered in accessories. Voltage, Current & Door sensors are not included in the accessories.

*: Current alarm settings are pre-fixed from factory as per requirements of WHO/PQS/E006/DS01.2. Other settings are available on request. The Recommended condition is defined as per clause no. 4.2.6 of WHO/PQS/E006/DL01.2 specification protocol.

| Order Code | Description |

| 99943 | Level-1: Data Logger with M2M Interface |

| 99942 | Level-2: Integrated EMD with Local communication |

| 99941 | Level-3: Integrated EMD with Local and remote communication |

| 99949 | Level-3: Integrated EMD with Local and remote communication (GSM International Add ON) |

Accessories

- Temperature Sensor(s)

- Calibration certificates for Temperature Sensor and Device

- USB Type-C to C cable

- 15 V DC, 2A Power Supply Adapter

- SMPS with Power output 15 V DC, 3 A, 35 W

- Cable Assembly for Analog/Digital Interface

- Cable Assembly for Power port*

* Accessories will be provided as per the request and selected order code for the data logger.

key for more than 10 seconds.

key for more than 10 seconds.