Significance of Temperature Monitoring in Cold Storage

Many products, such as vaccines, blood plasma, dairy, and pharmaceuticals, have specific temperature requirements to maintain their quality. Deviations from these temperatures can lead to spoilage, loss of nutritional value, or reduced effectiveness of medications. Cold storage helps slow down the growth of bacteria and other microorganisms, preserving the freshness of products. Accurate temperature monitoring assures that conditions remain within the optimal range, preventing premature spoilage and reducing waste. Regular temperature monitoring helps companies comply with these regulations, avoids legal issues and assure that consumers are protected from hazardous conditions.

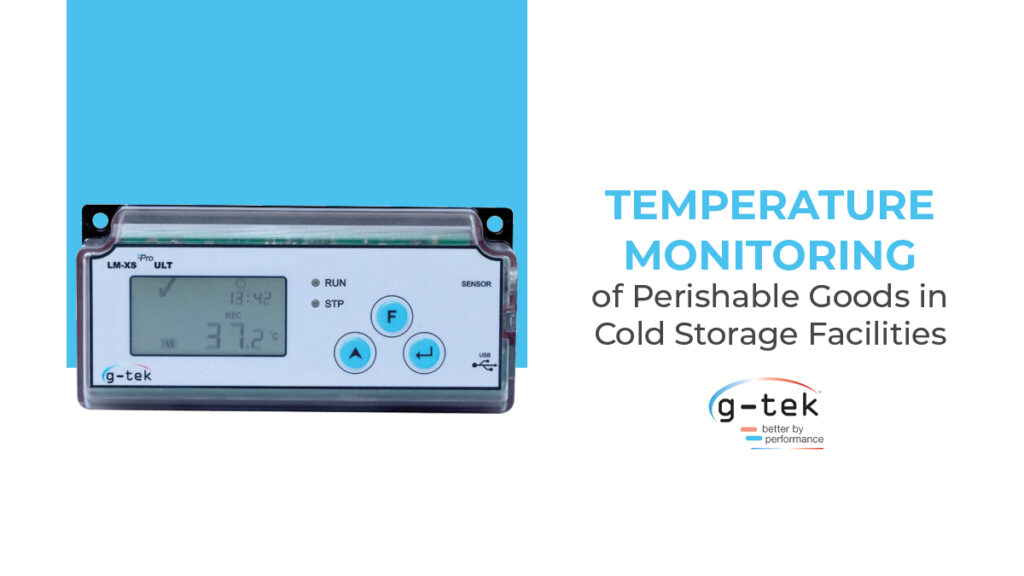

Product Overview

The LM-XS Pro ULT (Ultra Low Temperature) Data logger is an external sensor user programmable multi use single channel data logger meeting the requirements of WHO/ PQS /E006/TR06.4. It displays “ü” for compliance & “X” for temperature breaches. It triggers audio-visual alarms for temperature fluctuations. It retains data for 120 days, allowing users to review historical data for the past 30 days directly on temperature monitoring devices.

Key Feature

- Real time monitoring: These devices are ideal for cold storage monitoring as they continuously monitor and record data.

- Communication port: The recorded data can be easily downloaded to a computer using a USB connection.

- Measuring range: Record temperature from -200 °C to + 200 °C.

- Data storage: It has capacity to preserve the data of last 120 days.

- Download: The user can easily download the recorded data in PDF and Excel formats via USB port.

- Software Compatibility: The LmView-XS-E006 software is compatible with windows operating systems supported by Microsoft.

- Data Logging: The software enables user-programmable logging intervals, User can add tags for alarm, sensor open and time settings.

- Audio Visual Alarm: Display temperature readings on the screen, accompanied by ▲ or ▼ arrows indicating high or low alarms, along with a bell symbol. The buzzer will sound in the event of temperature breaches.

G-Tek’s temperature monitoring solutions in cold storage facilities are the linchpin of a successful cold chain. It continuously monitors, record, and report temperature conditions in real-time significantly enhances quality assurance initiatives. By offering real-time temperature monitoring, extensive coverage across a wide temperature range, flexible intervals for data logging, and compatibility with user-friendly software, these loggers are indispensable for making informed decisions.