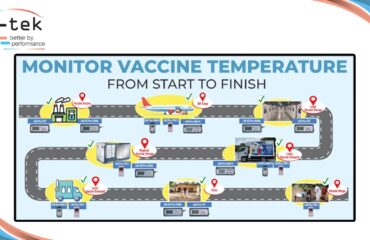

The Role of Temperature Management in Vaccine Distribution

Temperature-sensitive items like vaccines require careful handling due to their sensitivity to temperature fluctuations. Improper storage conditions and inadequate cooling equipment during transportation and distribution significantly impact their efficacy and render them ineffective or even harmful if administered. Therefore, it is imperative to handle vaccines with extreme care to preserve their integrity. At each step along the entire journey starting from their production in manufacturing facilities and continuing until they are safely delivered to their intended recipients.

The deployment of vaccine data loggers serves as a vital tool for detecting this cold chain gap.

Conforms to WHO PQS Guideline

The World Health Organization has established comprehensive guidelines for upholding performance quality and safety (PQS), regarding temperature monitoring devices employed in vaccine storage and transportation. G-Tek LM pro IN074 is compiles with norms specifically WHO/PQS/E006/TR07.4.

Product Overview

The LM IN074 series presents single-use, economically viable, and reliable 40-day Electronic Shipping Indicators, ideally crafted for meeting vaccine procurement and transportation demands. There are 4 models to choose from, based on the vaccines being transported Type Prevenar, Type Rotateq, Type A/B and Type C.

| Model | Alarm 1 | Alarm 2 | Alarm 3 |

| Type Prevenar | >= 40 °C | >= 30 °C | <= -0.5 °C |

| Single event > 1 hour | Cumulative > 10 hours | Single event > 1 hour | |

| Type Rotateq | >= 27 °C | >= 17 °C | <= -25°C |

| Single event > 1 minute | Cumulative > 2 hours | Single event > 1 minute | |

| Type A/B | >= 45 °C | >= 30 °C | >= 10 °C |

| Single event > 1 hour | Cumulative > 10 hours | Cumulative > 20 hours | |

| Type C | >= 45 °C | >= 30 °C | <= -0.5 °C |

| Single event > 1 hour | Cumulative > 10 hours | Single event > 1 hour |

The display indicates “ ✔” if the product has remained within exposure limits. If the product is exposed beyond time temperature limits as specified based on the type of vaccine, the display shows “X”. The devices comes with the shipment card.

Key Feature

- Temperature Monitoring: The devices consistently oversees and logs data throughout the transportation process.

- Operating range: It record temperature from -30 °C to + 60 °C (-22 °F to +140 °F)

- Data Logging: The appliance comes with the factory set logging interval of one minute. One can easily view event data (TAG) with a timestamp in report.

- Communication Port: Its mini USB port simplifies the process of transferring recorded data from the logger to a computer or other external device.

- Software Compatibility: The LMView IN074 software is tailored for seamless compatibility with Windows operating systems supported by Microsoft.

- Data storage: It has a 40-day capacity to store temperature data points, and users can access and view the complete dataset directly on the device.

- Visual Alarm: The device employs ‘▲‘ and ‘▼‘ symbols for visual temperature alerts, allowing users to identify temperature breaches above or below the set range.

- Download: Users can quickly access, retrieve, and analyze data from the devices. Via mini USB port.

G-Tek Electronic Shipping Indicators play a critical role in maintaining vaccines safety during transit by monitoring and recording temperature data and providing visual alerts for temperature breaches. These indicators are essential, as they provide the necessary evidence of vaccine safety that pharmaceutical companies and supply chain managers require-certifying vaccine safety and efficacy.