Nothing spoils someone’s day in logistics carrying perishables that get rejected, as the products experience severe hot and cold temperatures. Product rejections are the most common in the food industry, and every time it happens, it creates a chain of reactions negatively influencing the shippers and carriers.

Shippers often require filing a claim to recover their losses. The process results in a lot of anxiety due to the potential cost of damages. The shippers expect someone would pay for the losses, which often causes heated conversations with accusations and blaming each other.

What are Temperature Data loggers?

Temperature data loggers are essential for temperature and humidity monitoring and are employed in the industrial sector, where temperature and humidity play a major role. The device often called a temperature monitor, records temperature over a definite period. The device automatically collects, monitors, and stores information so that you can prepare a report later.

Application of Temperature Data Loggers In Shippers

Temperature data loggers have numerous applications, especially when shipping specific goods. These include:

Epoxy, chemical, and varnish

These are temperature-sensitive products. If you keep these products outside the temperature range, they experience degradation and sometimes reduce their shelf lives. Temperature data loggers record and monitor temperature, helping to prevent degradation.

Food, flower, meat, and dairy products

To ensure the safety and quality of food products, it is essential to monitor the storage conditions. The temperature data loggers monitor the storage of products to carry effective shipping without compromising the quality. The devices offer continuous updates and ensure maintenance of optimum temperatures.

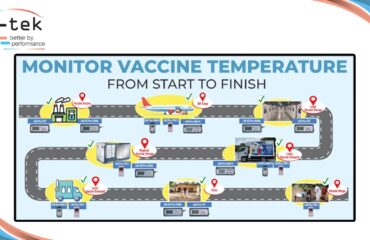

Vaccine and pharmaceuticals

These are the key components that prevent the occurrence and spread of disease. Therefore, it is essential to handle them precisely under perfect temperatures. Using temperature data loggers help in taking a reading at regular intervals for a complete overview.

Why Use Temperature Data Loggers While Shipping Goods?

Logistics professionals are responsible for ensuring that their shipments arrive on time without experiencing any damage or spoilage. Logistics managers have limited visibility into whether their providers track and maintain temperatures correctly. Some shippers require their carriers manually record a cold chain custody form.

Often carriers send an image of their reefer temperature to communicate with their customer that was following proper instructions. However, these methods offer limited data and fail to identify whether these loads experienced temperature deviations during transit. Modern temperature data loggers regularly capture accurate temperatures at the shipment’s origin and destination.

You can track the results of every shipment, ensuring that your perishable commodities remain tracked throughout the journey. Monitoring the interior temperature and humidity of containers helps evaluate the suitability of the packaging system chosen for the specific goods.

Why Choose G-Tek?

G-Tek is one of the leading manufacturers of temperature data loggers and ensures to offer the users the best quality data loggers for usage. A team of adequately trained and experienced professionals manufactures premium quality products adhering to all set standards in all aspects. We take perpetual inventory and have a daily-randomized internal audit to ensure that every department and person adheres to the quality.